The Craftsmanship Legacy of Walsall

Walsall has a rich history as a leatherworking hub, particularly for equestrian products. For generations, craftsmen here have created saddles, harness, and other leather goods, and Walsall Leather Skills Centre plays an essential role in preserving this heritage.

We understand the value of preserving traditional craftsmanship in a world that often favours quick, mass-produced items. Our commitment to offering extensive courses stems from a desire to keep these skills alive, ensuring they’re passed down through generations.

Harness Making

In the world of leatherworking harness making stands as a pinnacle of craft, precision, and tradition. For centuries, harness has been essential to working horses and, as equestrian sports evolve, the need for well-crafted, durable harness remains as important as ever.

Harness is critical in ensuring control, safety and comfort during various equestrian activities. Whether it’s for driving, working, or show, a harness needs to withstand significant wear and tear while distributing weight and pressure comfortably for the horse.

Harness making is an art form demanding an understanding of materials, mechanics and the unique needs of horses in relation to the carriage .

Horses use different types of harness depending on their role:

- Driving Harness: Mainly used for travelling; with a two wheeled vehicle this harness needs to distribute the balanced weight of the vehicle on the horse’s back. Other types of turnout might require a multiple of horses and therefore the necessary harness to function with the carriage.

- Working Harness: Often used in agriculture, these harnesses are designed for strength and durability. They require extra reinforcement in key areas due to the heavy loads they bear.

- Show Harness: These harnesses emphasise aesthetics as much as functionality. They involve detailed finishing work, high-quality leather, and intricate hardware to make a strong visual impact during shows.

Skill and Dedication

Harness making is a discipline that requires dedication, precision and a deep respect for both craftsmanship and equestrian needs. Every stitch, cut and piece must be precisely executed to create a harness that is not only functional but also comfortable and long-lasting. The skills taught at Walsall Leather Skills Centre help students move beyond basic assembly, guiding them to understand how each piece of the harness interacts with the horse’s movements and provides safety and comfort for the horse.

Handmade harness embodies quality, tradition and care. By learning these skills, students become part of a select group of artisans committed to producing high-standard, customised equipment that honours the craft’s heritage.

At Walsall Leather Skills Centre, we are proud to offer Intermediate and Advanced Harness Making courses, designed to preserve these skills, ensuring they continue to be relevant and accessible to the next generation of leatherworkers.

The journey through harness making is one of skill, dedication and continuous learning—a journey we’re passionate about sharing.

In today’s equestrian world, where customised and well-fitted is highly valued, harness makers with traditional skills are increasingly sought after. We prepare students to meet this demand by providing an education rooted in both historical techniques and modern applications, setting them apart in the industry.

Key Skills Taught in Our Harness Making Courses

Our courses go beyond basic skills, empowering students to achieve City & Guilds certifications and learn the intricacies of one of leatherworking’s most challenging disciplines. Our courses are structured to cover every essential skill, from the basics to more advanced techniques. Here’s what students will learn:

- Measurement and Fitting: The foundation of a good harness starts with accurate measurements. Students learn how to take precise measurements of both the horse and the harness components to ensure a comfortable, custom fit.

- Leather Selection: Different parts of the harness require different types of leather based on strength, flexibility and wear resistance. Our harnessmakers teach students how to select the best leather for each harness component.

- Cutting and Shaping: Students practice cutting leather to shape, learning techniques to ensure even edges and balanced proportions.

- Hand Stitching and Assembly: We emphasise the importance of strong, durable stitching. Students practice hand-stitching techniques that add strength and aesthetic appeal, as well as learning how to assemble all components accurately.

- Hardware Selection and Attachment: Buckles, rings and other hardware are essential for functionality and durability. Students learn to choose and attach hardware suited for the harness’s purpose.

- Finishing Techniques: Adding a professional finish not only improves durability but also enhances the visual appeal of the harness. Our courses cover edge-finishing, polishing, and leather conditioning.

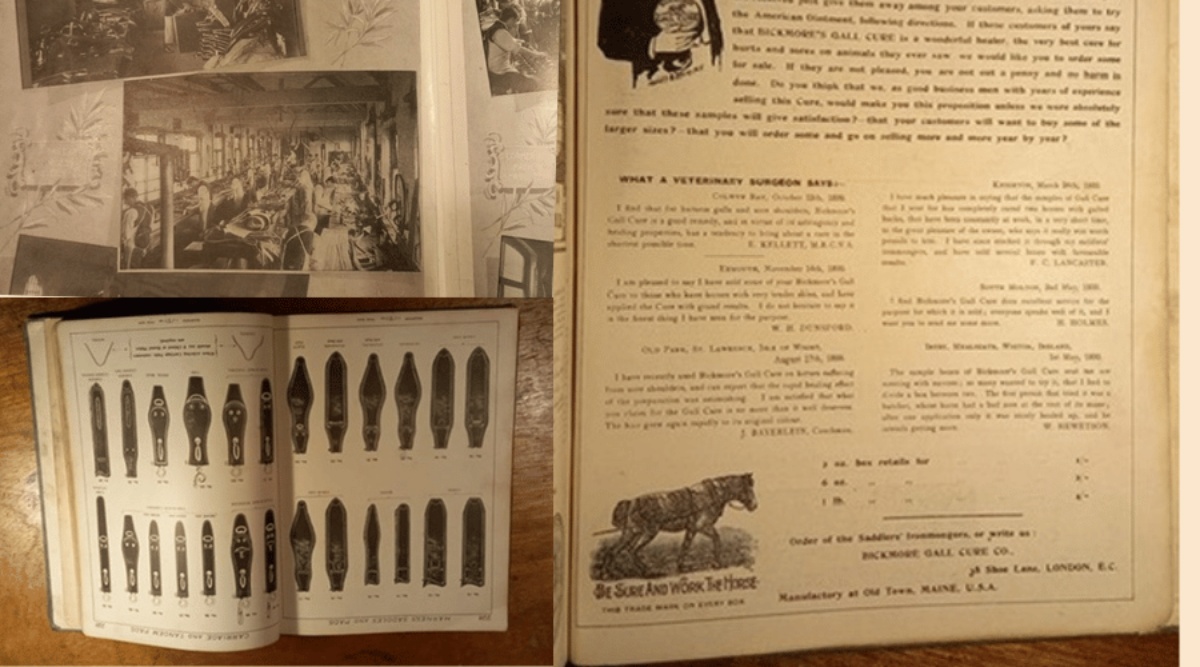

Here are some of the pieces that are made in the Walsall Leather Skills Centre and the high quality finish that can be achieved.

Intermediate Harness

Our Intermediate Harness Making course is ideal for those who have completed the Intermediate Bridle course and are ready to dive deeper into the craft.

This two-week course introduces essential elements of harness making, including pattern making, leather selection, and complex assembly techniques. The course is structured into two separate weeks, giving students time to practice independently between sessions.

An example of the processes within the intermediate harness course at the Centre.

Course Breakdown: Week-by-Week and Day-by-Day

Week 1: Foundational Components

- Monday: Short Tugs – An introductory lecture discusses the difference between harness and bridle work, the types of leather used, and the specific purpose and function of the components made during these two weeks. Students practice making a set of short tugs with 3 evenly spaced keepers on each tug, an exercise that demands accuracy and precision.

- Tuesday: Dock – Students learn how to make a pattern out of a few given measurements. Using their own pattern students create two docks, focusing on two different stitching techniques. (and understanding the gap between theory and function.)

- Wednesday: Breeching Seat – This lesson introduces a heavy duty harness part with a reinforced section known as a “wear piece.” Students also explore the technique of creating a ‘raised strap’ by skiving edges or using a fillerfor a domed effect.

- Thursday: Breeching Straps – Students complete the breeching seat and make a pair of breeching straps, introducing them to an additional assembly technique.

- Friday: Crupper – The final lesson covers creating a crupper, a key piece required for the Level 2 Skills Test.

Week 2: Advanced Components and Assembly

- Monday: Hipstrap – Focussing on cutting and hole punching skills, students work on pattern creation, leather cutting, and accurate measuring techniques.

- Tuesday: Chapes on Docks – This session delves into gluing and stitching methods, teaching students to work with multiple leather layers and well proportioned fixed keepers, neatly assembled.

- Wednesday: Boxloops – A day to explore the construction and chequering techniques involved in making box loops. Boxloop chequering requires a lot of practice and this day should be seen as an in depth introduction to the art of making boxloops.

- Thursday: Repairs/Workshop – An opportunity to apply skills to real-world repair tasks. Students are encouraged to bring any harness repairs they have. If there isn’t enough time to get the repair done we can talk through the process.

- Friday: Skills Test – Students submit prepared pieces and complete a timed skills test and written assessment.

Support and Community: Students gain access to a WhatsApp group for real-time support and video demonstrations between sessions. A well-equipped home setup is essential for continued practice, as students are encouraged to refine their skills outside of class.

Advanced Harness

For those who wish to master the art of harness making, our Advanced Harness Making course at Level 3 is the ultimate challenge. This course takes students through the intricacies of crafting a complete harness, building upon the skills gained in Level 2. It is designed for individuals with a deep commitment to the craft, as the coursework requires extensive homework and spans over 12 months, allowing ample time for practice between teaching weeks.

At the heart of the Advanced Harness course is the creation of a Gig Saddle—a piece with a rich history. Gig Saddles were originally designed for light, two-wheeled carriages known as “gigs,” popular in the 18th and 19th centuries. These saddles, used in harness racing and driving, had to be comfortable for the horse while also being robust enough to support the balanced weight of the carriage. Today, they are valued not only for their functionality but also for their aesthetic appeal, as they often feature intricate stitching and high-quality leatherwork.

The Gig Saddle is both a functional and decorative element, showcasing the craftsmanship and attention to detail that defines a skilled harness maker. By mastering the Gig Saddle, students pay homage to a piece of equestrian history while gaining a high-level skill in leatherwork.

Here is a Gig Saddle tree and close up of a finished version.

Advanced Harness Course in Weeks

Week 1: Foundation and Design Decisions

- Day 1: Theory and Design – Covers harness fit, demonstration using our plastic horse, and pattern making for various components. Students start cutting out traces, backband, and belly band.

- Day 2-5: Reins, Round Tugs, Girth, Short Tugs – Students refine their design choices, focusing on each component to ensure accurate measurements and secure assembly.

Weeks 2-4: Specialised Components

- Week 2: Components like Blinkers, Cheeks, Noseband, and Headpiece are crafted, emphasising the importance of detail to achieve the most comfortable fit for the horse.

- Week 3: Facedrop, Martingale, Breastcollar, and Neckstrap – Students dive into creating these pieces, learning how they contribute to a set of harness.

- Week 4: Breeching, Hipstrap, Breeching Straps, Dock, and Lined Crupper – These lessons focus on making a more refined style of the components made during the intermediate harness course.

Weeks 5-7: Gig Saddle Creation and Final Skills Test

- The culmination of the course is the Gig Saddle, requiring advanced skills and showcasing the craftsmanship students have developed. The Level 3 Skills Test requires students to present a patent leather private driving show set and complete a timed assessment, demonstrating their proficiency.

Join Walsall Leather Skills Centre and Become Part of a Legacy

Harness making is more than a skill; it’s a commitment to quality and tradition. Join us on this journey to master harness making and become part of Walsall’s proud legacy of leatherworking.

Click below to view our course pages: